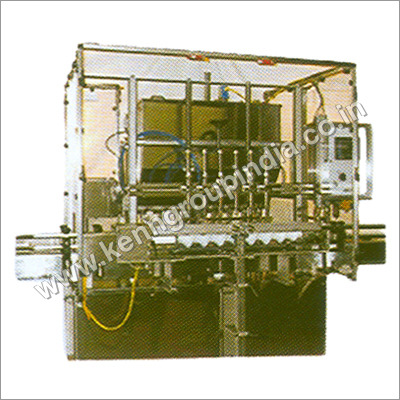

Sterilizers

Sterilizers Specification

- Power Supply

- AC

- Noise Level

- <60 dB

- Features

- Corrosion Resistant, Robust Construction, Overheat Protection

- Filling Range

- Flexible (customizable as per use)

- Application

- Medical, Laboratory, Pharmaceutical, Food Industry

- Usage

- Sterilization of Instruments and Consumables

- Type

- Sterilizer

- Material

- Stainless Steel

- Feature

- Automatic Timer, Digital Display, Safety Lock

- Auxiliary Packaging Machine Type

- Sterilization Unit

- Capacity

- 50 L to 500 L (customizable)

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- Microprocessor Based Digital Control Panel

- Drive Type

- Electric

- Power

- 2 kW to 6 kW (depends on capacity)

- Voltage

- 220V / 380V

- Color

- Silver

- Sealing Type

- Gasket

About Sterilizers

Within a short span on one year we have marked a special place in the market by manufacturing and supplying a qualitative range of Sterilizers. These are used for steam heating of plastic bottles. We manufacture these machines under the observation of our experienced manpower using the best quality materials. The materials are procured from the authentic vendors of the market. Our Sterilizer Machine are precisely checked on quality and functionality parameters before offering to the clients at reasonable price.

Features:

- Excellent functionality

- Rugged construction

- Impeccable performance

Further Details:

We manufacture sterilizers viz. ethylene oxide sterilizers (ETO), for sterilizing plastic dispensable, plastic bottles etc. basically this technique of sterilization is used when the objects to be sterilized cannot be heated to high temperature.

Advanced Microprocessor Control

Operated via a digital, microprocessor-based control panel, these sterilizers provide users with precise temperature, timing, and operational settings. The computerized interface ensures every sterilization cycle achieves optimal results, reducing human error and enhancing reliability across industries demanding strict hygiene and cleanliness.

Customizable for Diverse Needs

Available in capacities from 50 L to 500 L, our sterilizers can be tailored to meet specific requirements for filling range, sealing type, and operational parameters. This flexibility makes them ideal for a variety of uses, from small labs and clinics to large pharmacies, hospitals, and food processing plants.

Built for Safety and Durability

Constructed from high-grade stainless steel, these units offer corrosion resistance and robust durability even in demanding environments. Safety features, such as automatic timer, overheat protection, and secure safety locks, ensure user protection during operation while maintaining consistent sterilization quality.

FAQs of Sterilizers:

Q: How does the stainless steel sterilizer work for different applications?

A: The sterilizer utilizes electric-powered heating elements controlled by a microprocessor digital panel to achieve and maintain optimal temperatures. Its automatic cycles, customizable filling range, and durable gasket sealing make it effective for sterilizing instruments and consumables in medical, laboratory, pharmaceutical, and food industry settings.Q: What are the benefits of using a stainless steel sterilizer with automatic digital controls?

A: The digital microprocessor control ensures accurate temperature and timing, reducing the risk of incomplete sterilization or human error. Users benefit from enhanced safety features, robust construction, and the ability to automate repetitive processes, leading to higher efficiency and safety in critical environments.Q: When is this sterilizer typically used during operations?

A: This sterilization unit is utilized before, during, or after procedures that require sterile instruments and materials. It is essential in preparation phases and in between uses of reusable instruments to ensure contamination-free operations in medical, laboratory, and pharmaceutical contexts.Q: Where can the sterilizer be installed and used?

A: Designed for versatility, the sterilizer can be installed in hospitals, laboratories, pharmaceutical manufacturing units, and food processing facilities. Its robust design allows it to function safely and efficiently in a variety of environments requiring high standards of cleanliness.Q: What is the sterilization process in these units?

A: The process involves placing items inside the stainless steel chamber, selecting the desired cycle via the digital control panel, and allowing the unit to heat to the required temperature. The automatic timer and overheat protection ensure precise, safe operation until the cycle is complete, after which items are safe for use or packaging.Q: How is safety ensured during the sterilization cycle?

A: Safety is prioritized through features like automatic safety locks, overheat protection, digital displays for monitoring, and a robust construction that withstands pressure and heat. These mechanisms collectively prevent accidental opening, overheating, and operational mishaps.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Packaging Machine Category

Dangler Packing Machine

Filling Range : Adjustable

Auxiliary Packaging Machine Type : Other, Automatic Packing Machine

Noise Level : Low

Power Supply : Single Phase

Type : Other, Dangler Packing Machine

Control System : Other, PLC Control Panel

Capping Machine

Filling Range : Adjustable as per Bottle Size

Auxiliary Packaging Machine Type : Other, Bottle Packaging Machinery

Noise Level : Low

Power Supply : AC

Type : Other, Capping Machine

Control System : Other, PLC Control Panel

Rinser Filler Capper

Filling Range : 200 ml 2000 ml

Auxiliary Packaging Machine Type : Other, Beverage Bottle Packaging Machinery

Noise Level : 75 dB

Power Supply : AC Electric

Type : Other, Rinser Filler Capper Machine

Control System : PLC Control

|

KENN ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry