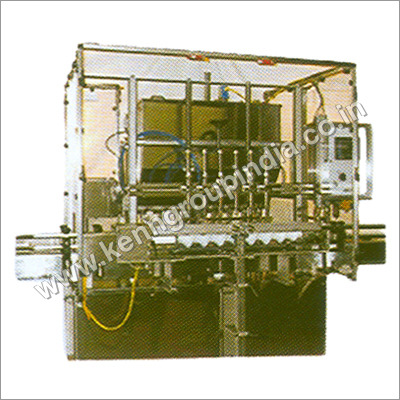

Capping Machine

Capping Machine Specification

- Filling Range

- Adjustable as per Bottle Size

- Noise Level

- Low

- Usage

- Sealing and Capping Bottles

- Application

- Bottling and Packaging Industry

- Power Supply

- AC

- Type

- Capping Machine

- Material

- Stainless Steel

- Auxiliary Packaging Machine Type

- Bottle Packaging Machinery

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control Panel

- Drive Type

- Electric

- Power

- 1.2 kW

- Voltage

- 220V/380V

- Weight (kg)

- Approx. 350 kg

- Dimension (L*W*H)

- 2000 mm x 900 mm x 1850 mm

- Color

- Silver/Grey

- Sealing Type

- Screw/ROPP

About Capping Machine

With the support of our experienced personnel, we are engaged in manufacturing and supplying superior quality Capping Machine. These machines are used for capping purposes in bottles and pouches. We use the finest quality materials to manufacture these machines. Our quality controllers check the Capping Machine on performance and functionality parameters. We are able to deliver our machines to the valuable clients at reasonable price and within the stipulated time frame.

Features:

- Robust construction

- Long working life

- Excellent quality

Further Details:

Capping machines are with various specifications to suit different capping needs and types of capping viz. pre threaded, ROPP and Lug capping. Irrespective of the type of capping, the machine is equipped with pick and place type capping which is the most precise technology that delivers reliable capping with almost nil rejections especially for pre threaded and lug caps.

Speed: 40- 200 bpm

Advanced Automation for Superior Efficiency

The capping machine integrates a programmable PLC control system and touchscreen interface, allowing for seamless adjustments and rapid changeovers between bottle sizes. Its variable conveyor speed and automatic cap feeding via a vibratory bowl streamline the capping process, reducing human intervention and boosting productivity within modern bottling lines.

Safety, Reliability, and Centralized Maintenance

Built for industrial workspaces, this machine prioritizes operator safety with its emergency stop button and overload protection system. Centralized lubrication minimizes maintenance downtime, ensuring sustained reliability and longevity. Its robust build and low noise level create a safe and comfortable working environment for your staff.

FAQs of Capping Machine:

Q: How does the capping machine achieve a production accuracy of at least 99%?

A: The machine employs computerized PLC controls, precise servo motors, and a high-precision vibratory bowl cap feeding system, ensuring consistent cap placement and sealing. These features work together to minimize errors and maintain a production accuracy of 99% or higher.Q: What types of bottles and caps are supported by this machine?

A: With adjustable settings to fit various bottle sizes and both screw and ROPP sealing types, this capping machine is suitable for a wide array of bottles commonly used in the bottling and packaging industry.Q: When is it recommended to utilize the emergency stop feature?

A: The emergency stop button should be used immediately in case of equipment malfunction, unexpected objects on the conveyor, or any unsafe operating condition, to halt the machine and prevent accidents or damage.Q: Where is centralized lubrication applied in this machine, and why is it beneficial?

A: Centralized lubrication is distributed to crucial moving parts, reducing friction and wear. This leads to easier maintenance, increased durability, and minimal production downtime.Q: What is the process for adjusting the filling and capping range to fit different bottle sizes?

A: Users can easily adjust filling and capping parameters via the PLC touchscreen panel, allowing for rapid changeovers and optimal alignment for each bottle size, saving time and ensuring precision.Q: How does the automatic vibratory bowl cap feeding system enhance production?

A: The vibratory bowl feeds caps automatically and arranges them correctly, reducing manual labor and speeding up the capping process, which enhances overall throughput and consistency.Q: What are the primary benefits of using this automatic capping machine in the bottling industry?

A: Key benefits include high production accuracy, adjustable operation tailored to various bottle sizes, robust safety features, low noise levels, and reduced maintenance needshelping operators achieve dependable, high-volume output.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Packaging Machine Category

Sterilizers

Control System : Other, Microprocessor Based Digital Control Panel

Computerized : Yes

Auxiliary Packaging Machine Type : Other, Sterilization Unit

Features : Corrosion Resistant, Robust Construction, Overheat Protection

Color : Silver

Sealing Type : Other, Gasket

Rinser Filler Capper

Control System : PLC Control

Computerized : Yes

Auxiliary Packaging Machine Type : Other, Beverage Bottle Packaging Machinery

Features : Touch Screen HMI, High Precision Filling, Fast Changeover

Color : Other, Silver/Grey

Sealing Type : Other, Screw/ROPP Cap

Dangler Packing Machine

Control System : Other, PLC Control Panel

Computerized : Yes

Auxiliary Packaging Machine Type : Other, Automatic Packing Machine

Features : User Friendly, High Output, Safe Operation

Color : Silver

Sealing Type : Other, Heat Seal

|

KENN ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry