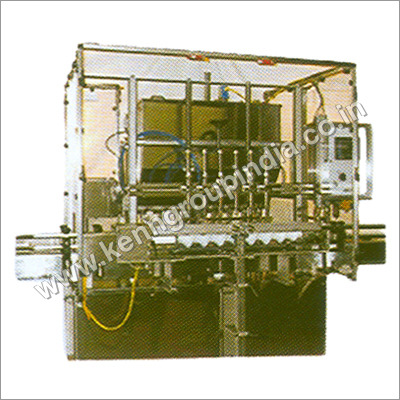

Dangler Packing Machine

Dangler Packing Machine Specification

- Power Supply

- Single Phase

- Noise Level

- Low

- Usage

- Industrial Packaging

- Application

- Dangler Label Packaging

- Filling Range

- Adjustable

- Features

- User Friendly, High Output, Safe Operation

- Type

- Dangler Packing Machine

- Material

- Stainless Steel

- Auxiliary Packaging Machine Type

- Automatic Packing Machine

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control Panel

- Drive Type

- Electric

- Power

- 2 kW

- Weight (kg)

- Approx. 350 kg

- Dimension (L*W*H)

- 1800 x 800 x 1800 mm

- Color

- Silver

- Sealing Type

- Heat Seal

About Dangler Packing Machine

Backed with know-how and great command in this domain, we are counted as a leading manufacturer and supplier of an exclusive range Dangler Packing Machine. We use the finest quality materials to manufacture these machines under the observation of our expert professionals. Our Dangler Packing Machine is available in different customized size and design specifications. Our quality checkers check these machines on performance and efficiency parameters before offering to the clients at reasonable price.

Features:

- Sturdy construction

- Unmatched quality

- High functional fluency

Further Details:

This is another technology milestone in our track records which was an innovative concept to pack the tubes in displayable transparent danglers along the label with alternate tubes in 180 degree orientation with complete automatic feeding of tubes. Similar machines are also available for packing cartons in danglers.

Speed: 4-6 danglers per minute.

Advanced Automatic Packaging

Equipped with a computerized PLC control panel and an electric drive, the Dangler Packing Machine automates the packaging of dangler labels with minimal operator intervention. Its adjustable parameters allow for varied filling needs while ensuring precise heat sealing for secure packaging outcomes.

Reliable Industrial Performance

This stainless steel machine is engineered to withstand rigorous industrial use. Its low noise emission, robust construction, and 2 kW power supply support continuous operations in busy packaging environments, making it a trusted choice for businesses seeking consistent, high-output solutions.

User-Centric Design and Safety

User safety and operational simplicity are integral to the design. The user-friendly interface streamlines setup and daily operation, while integrated safety mechanisms and high automation minimize risks, supporting smooth and secure industrial packaging processes.

FAQs of Dangler Packing Machine:

Q: How does the Dangler Packing Machine enhance packaging efficiency?

A: The Dangler Packing Machine automates the entire label packaging process, from filling to heat sealing, minimizing manual intervention. With its computerized PLC control panel, it ensures precise and high-speed operations, resulting in greater throughput and reduced production time for industrial users.Q: What materials and packaging types is this machine suitable for?

A: This machine is specifically designed for dangler label packaging and is built from premium stainless steel, which offers both durability and hygiene. Its adjustable filling range and heat seal capability allow it to cater to various label sizes and packaging requirements.Q: Where can the Dangler Packing Machine be used?

A: Ideal for industrial and commercial packaging operations, this machine is suitable for large-scale production environments such as manufacturing facilities, packaging plants, and export businesses needing efficient and reliable label packaging solutions.Q: What is the installation process for this packaging machine?

A: Installation is straightforward due to its compact, integrated design. Simply position the machine in the desired location, connect the single-phase power supply, and use the PLC control panel for setup. Detailed instructions and support are typically provided by the manufacturer or supplier.Q: How safe and user-friendly is the operation of this machine?

A: The machine features a user-friendly interface designed for intuitive operation. Safety mechanisms are built-in to prevent operator hazards, and its low noise operation ensures a comfortable working environment, supporting secure and efficient workflows.Q: What are the main benefits of using this automatic packing machine?

A: Key advantages include high output, reduced manual labor, precise sealing, and adaptability to various dangler label sizes. Its robust stainless steel build and low maintenance requirements further enhance operational reliability and cost effectiveness for industrial packaging.Q: When is it ideal to invest in this equipment?

A: Businesses experiencing increased packaging demands or aiming to modernize their operations for higher consistency and efficiency should consider investing in this machine. Its automation and adaptability make it suitable for scaling up production and meeting export requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Packaging Machine Category

Sterilizers

Material : Stainless Steel

Computerized : Yes

Color : Silver

Voltage : 220V / 380V

Drive Type : Electric

Noise Level : <60 dB

Capping Machine

Material : Stainless Steel

Computerized : Yes

Color : Other, Silver/Grey

Voltage : 220V/380V

Drive Type : Electric

Noise Level : Low

Rinser Filler Capper

Material : Stainless Steel

Computerized : Yes

Color : Other, Silver/Grey

Voltage : 220 V/380 V, 50 Hz

Drive Type : Electric

Noise Level : 75 dB

|

KENN ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry