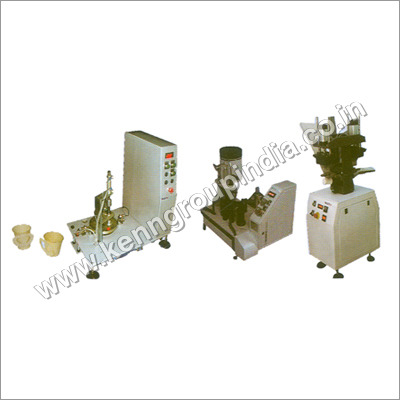

Cap Wad Assembly Machine

Price 1000000 INR/ Number

MOQ : 1 Number

Cap Wad Assembly Machine Specification

- Type

- Cap Wad Assembly Machine

- Material

- Mild Steel (MS) Structure

- Capacity

- 4000 to 7000 Pieces/Hour

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Based

- Drive Type

- Electric Motor Driven

- Power

- 2 HP / 1.5 kW

- Weight (kg)

- 850 kg

- Dimension (L*W*H)

- 2200 mm x 1000 mm x 1700 mm

- Color

- Industrial Grey/Blue

- Feeding System

- Vibratory Bowl

- Operation Mode

- Fully Automated with Touch Screen

- Production Line Compatibility

- High-speed Cap & Wad Assembly Lines

- Accessories

- Conveyor Belt; Safety Guards

- Maintenance

- Low/Minimal

- Noise Level

- Less than 75 dB

- Voltage

- 440 V AC, 3 Phase

- Cap Size Range

- 22 mm to 120 mm

- Filling Accuracy

- ± 2 mm

Cap Wad Assembly Machine Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100 Per Day

- Main Domestic Market

- All India

About Cap Wad Assembly Machine

Utilise this opulent offer and grab yours now-the Cap Wad Assembly Machine stands as a monumental innovation for high-speed production lines. Engineered with a mild steel structure and finished in an industrial grey/blue, this fully automated marvel features PLC controls and a vibrant touch screen interface. With an astonishing filling accuracy of 2 mm, low maintenance requirements, and a capacity to deliver 4000-7000 pieces per hour, it harmonises efficiency with reliability. Enjoy seamless operation through its vibratory bowl feeding system, all at a noise level below 75 dB.

Powerful Applications for Automated Assembly

The Cap Wad Assembly Machine is purpose-built for assembling caps and wads in rapid succession, making it indispensable for packaging and manufacturing facilities. Designed for intensive, continuous use, its automated operation suits both moderate and heavy-duty applications. Whether integrating into an existing high-speed line or setting up a new production process, this machine ensures consistent output with minimal supervision-perfect for maximizing productivity and ensuring prompt order fulfillment.

Pricing, Delivery, and Packaging Details

List price options for the Cap Wad Assembly Machine are available upon request, with competitive transport services provided for swift delivery to global ports. We ensure goods are dispatched from a prominent FOB port in India, with robust packaging details tailored for secure transit. Take advantage of our lowest price guarantee-request a sample as per our sample policy to evaluate the assembly machine before placing a bulk order. Customer satisfaction remains at the forefront of our service.

Powerful Applications for Automated Assembly

The Cap Wad Assembly Machine is purpose-built for assembling caps and wads in rapid succession, making it indispensable for packaging and manufacturing facilities. Designed for intensive, continuous use, its automated operation suits both moderate and heavy-duty applications. Whether integrating into an existing high-speed line or setting up a new production process, this machine ensures consistent output with minimal supervision-perfect for maximizing productivity and ensuring prompt order fulfillment.

Pricing, Delivery, and Packaging Details

List price options for the Cap Wad Assembly Machine are available upon request, with competitive transport services provided for swift delivery to global ports. We ensure goods are dispatched from a prominent FOB port in India, with robust packaging details tailored for secure transit. Take advantage of our lowest price guarantee-request a sample as per our sample policy to evaluate the assembly machine before placing a bulk order. Customer satisfaction remains at the forefront of our service.

FAQ's of Cap Wad Assembly Machine:

Q: How does the Cap Wad Assembly Machine ensure precise assembly of caps and wads?

A: The machine features a sophisticated vibratory bowl feeding system paired with a PLC-based control system and computerized automation, achieving a filling accuracy of 2 mm for consistent results.Q: What types of production lines is this assembly machine compatible with?

A: It is engineered for seamless integration with high-speed cap and wad assembly lines, making it highly suitable for both new installations and upgrades in modern production facilities.Q: When is it ideal to use this fully automated assembly machine?

A: This machine is optimal for scenarios requiring high throughput, low maintenance, and precision-especially in large-volume packaging or cap assembly processes where productivity gains are essential.Q: Where can customers export or source the Cap Wad Assembly Machine from?

A: We are a leading exporter, manufacturer, and supplier based in India, ready to dispatch this equipment to clients worldwide through reliable logistics and transport services.Q: What is the process for ordering, packaging, and receiving the machine?

A: Orders can be placed directly through our sales team. We provide secure, industry-standard packaging and organize transport via prominent FOB ports, ensuring safe and prompt delivery.Q: What are the benefits of using this automated assembly machine in industrial settings?

A: Key benefits include high production capacity, exceptional filling accuracy, robust safety features, low noise levels, minimal maintenance, and ease of operation via touch screen controls.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Automation Machinery Category

Cap Cutting Machine

Price 1000000 INR / Number

Minimum Order Quantity : 1 Number

Automatic Grade : Automatic

Control System : Other, PLC Control System

Material : Stainless Steel

Computerized : Yes

Flip Top Cap Closing Machine

Price 1000000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Control System : PLC Control

Material : SS

Computerized : Yes

Custom Designed Machines

Automatic Grade : Automatic

Control System : Other, PLC Based

Material : Mild Steel / Stainless Steel

Computerized : Yes

Automatic Feeders

Automatic Grade : Automatic

Control System : Other, PLC Based

Material : Stainless Steel

Computerized : Yes

|

KENN ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry