Custom Designed Machines

Custom Designed Machines Specification

- Bend Radius

- As per custom specification

- Type

- Custom Designed Machine

- Material

- Mild Steel / Stainless Steel

- Capacity

- Up to 5000 kg/hr (varies with design)

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Based

- Drive Type

- Electric Motor

- Screw Diameter

- 30 mm to 150 mm (customizable)

- Power

- 7.5 kW to 75 kW

- Weight (kg)

- 1200 9500 kg (depends on model)

- Dimension (L*W*H)

- Customized as per requirement

- Color

- Industrial Grey / Custom Options

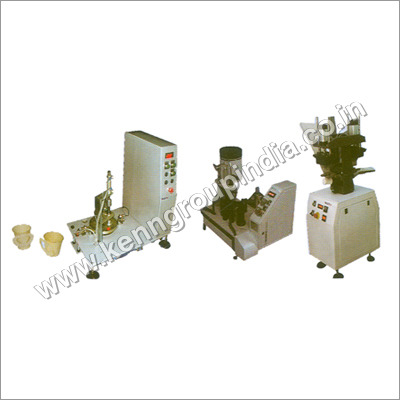

About Custom Designed Machines

We keep ourselves updated with the growing demand of the market, which helps us to provide an extensive range of Custom Designed Machines. Offered machines are manufactured by utilizing high grade components and advanced technology as per international quality norms. These machines are used for making different types of bottles for storing foods products. Available in different technical specifications, these Custom Designed Machines can also be customized as per clients specific need.

Features:

-

Easy to use

-

Operational fluency

-

Less maintenance

-

Noise-free operations

Versatile Engineering for Every Industry

Our custom designed machines are crafted to cater to a broad range of commercial sectors. By offering PLC-based automated control and customizable components, each machine meets unique operational demands efficiently. Flexible design capabilities allow integration into new or existing production environments seamlessly, enhancing productivity and reducing operational bottlenecks.

Precision Control and Customization

Equipped with advanced computerized (PLC) control systems, these machines ensure precision and ease of use. Every aspectfrom screw diameter to power outputcan be tailored, facilitating the creation of high-performance equipment that aligns with your production objectives. Customers can also choose from various material and color options, ensuring both durability and seamless integration with existing workflows.

FAQs of Custom Designed Machines:

Q: How are the custom designed machines tailored to specific requirements?

A: Each machine is designed based on your operational specifications, such as capacity, material, dimensions, and required output. Our engineering team collaborates closely with you to configure features like screw diameter, bend radius, power, and control systems for optimal performance.Q: What industries commonly use these custom designed machines?

A: Our machines serve diverse industries including food processing, plastics, pharmaceuticals, chemicals, and materials handling. Their versatility and robustness make them suitable for any industrial application requiring reliable high-capacity automation.Q: When should I consider investing in a custom designed machine?

A: You should consider a custom solution when standard machines do not meet your capacity, size, or process automation needs, or when your workflow necessitates specialized configurations for improved efficiency and output.Q: Where are these machines manufactured and can they be exported internationally?

A: All machines are manufactured in India, utilizing advanced manufacturing technologies. As a recognized exporter, we supply and support clients both within India and across global markets.Q: What is the process for ordering and customizing a machine?

A: Contact our sales team with your application requirements. Well conduct a needs analysis, followed by a design proposal, which is refined collaboratively. Once approved, the machine is built, tested, and delivered according to your specifications.Q: How are these machines controlled and monitored during operation?

A: Operation is fully automated through a Programmable Logic Controller (PLC) system. This ensures precision control, real-time monitoring, and simplified management, boosting productivity and minimizing the risk of operator error.Q: What are the main benefits of using a custom designed, automated machine?

A: The chief advantages include elevated productivity, adaptable integration, reduced labor requirements, increased accuracy, and the ability to scale or modify equipment as your production demands evolve.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automation Machinery Category

Wadding Machine

Price 1000000 INR / Number

Minimum Order Quantity : 1 Number

Computerized : Yes

Control System : PLC Control

Material : Stainless Steel

Color : Silver

Cap Folding Machine

Price 1000000 INR / Number

Minimum Order Quantity : 1 Number

Computerized : No

Control System : Other, Manual Switch Control

Material : Mild Steel

Color : Blue & Silver

Flip Top Assembly Machine

Price 1000000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Control System : PLC Control

Material : SS

Color : silver

Flip Closing Machine

Price 1000000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Control System : PLC Control

Material : SS

Color : silver

|

KENN ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry