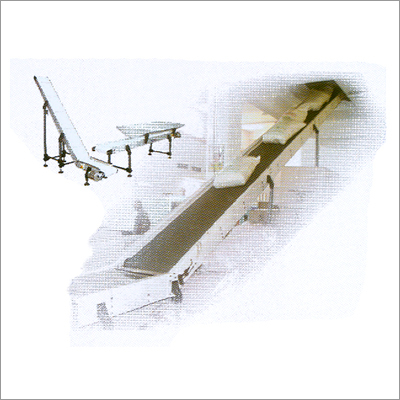

Automatic Feeders

Automatic Feeders Specification

- Type

- Automatic Feeders

- Material

- Stainless Steel

- Capacity

- Up to 100 kg/h

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Based

- Drive Type

- Electric Motor

- Screw Diameter

- 42 mm

- Power

- 0.55 kW

- Weight (kg)

- 75 kg

- Dimension (L*W*H)

- 700 mm x 350 mm x 950 mm

- Color

- Blue & White

About Automatic Feeders

Due to the varying requirements of the customers, we are engaged in manufacturing and supplying comprehensive range of Automatic Feeders. These feeders are manufactured by our well experienced personnel using the quality approved materials procured from the reliable vendors of the market. The clients can avail our Automatic Feeders from us at an affordable price and with customized design and model. We deliver our clients only defect free range of product within the committed time frame.

Features:

- High working efficiency

- Less maintenance

- Easy to install

Further Details:

We manufacture various type of feeders including vibratory feeders, conveyor feeders, hopper feeders, cassette feeders, counter feeders, special purpose feeders to meet any of the demands even the difficult ones.

Advanced PLC-Based Control

Equipped with a sophisticated PLC (Programmable Logic Controller) system, our automatic feeder offers precise and adaptable control over feeding operations. This advanced technology allows users to program and adjust settings for various materials, maximizing consistency and efficiency during production.

Durable Construction & Efficient Design

Manufactured using high-quality stainless steel, this feeder withstands rigorous use and is resistant to corrosion. The compact dimensions and electric motor drive make installation straightforward, while the 42 mm screw diameter supports a steady material flow, up to 100 kg/h, for uninterrupted automation.

Versatile Application Across Industries

Ideal for industries needing controlled material input for processing, our automatic feeder supports a wide range of applications. Its automated and computerized operation reduces the need for manual input, lowers labor costs, and enhances workplace safety in multiple industrial environments.

FAQs of Automatic Feeders:

Q: How does the PLC-based control system enhance the automatic feeders efficiency?

A: The PLC-based control system allows operators to program and monitor feeding parameters with high accuracy, ensuring materials are dispensed consistently. This automation reduces manual errors, optimizes workflow, and enables seamless integration with existing production lines.Q: What are the primary benefits of using this automatic feeder for industrial processes?

A: Key benefits include consistent material flow, reduced labor costs, increased safety due to minimal manual intervention, and improved operational efficiency. Its stainless steel construction also guarantees durability and easy maintenance.Q: When should I consider choosing a feeder with a 100 kg/h capacity and 42 mm screw diameter?

A: Choose this feeder model if your application requires moderate to high material throughput with precise control. Its especially suitable for industries needing continuous, automated feeding with consistent volume throughout production cycles.Q: Where can the automatic feeder be integrated within industrial workflows?

A: This automatic feeder can be seamlessly integrated into various stages of industrial workflows, such as material transfer, mixing, packaging, or extrusion lines, wherever automated, controlled feeding is essential.Q: What is the process for installing and operating the automatic feeder?

A: Installation is straightforward due to its compact dimensions and electric motor drive. Once positioned, users can configure the feeder using the PLC interface, setting parameters for material type and feed rate before commencing automated operation.Q: How does the stainless steel build contribute to the feeders usability and lifespan?

A: Stainless steel construction provides excellent strength, resists corrosion, and is easy to clean, making the feeder suitable for rigorous industrial use and extending its service life even in challenging environments.Q: What are the usage recommendations to maximize the benefit of this automatic feeder?

A: Ensure proper installation, routinely monitor PLC settings for optimal performance, and perform regular maintenance on the screw and motor components. Following these guidelines will maximize efficiency and prolong the feeders operational lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automation Machinery Category

Cap Folding Machine

Price 1000000 INR / Number

Minimum Order Quantity : 1 Number

Color : Blue & Silver

Automatic Grade : SemiAutomatic

Control System : Other, Manual Switch Control

Material : Mild Steel

Flip Closing Machine

Price 1000000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Color : silver

Automatic Grade : Automatic

Control System : PLC Control

Material : SS

Conveyor System

Color : Blue & Silver

Automatic Grade : Automatic

Control System : Other, PLC Control Panel

Material : Mild Steel & Stainless Steel

Shoulder Cap Assembly Machines

Color : Industrial Grey

Automatic Grade : Automatic

Control System : PLC Control

Material : Stainless Steel

|

KENN ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry