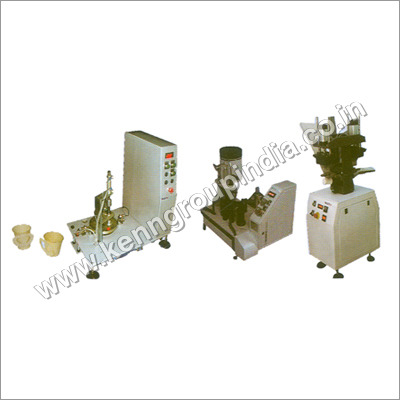

Shoulder Cap Assembly Machines

Shoulder Cap Assembly Machines Specification

- Type

- Shoulder Cap Assembly Machine

- Material

- Stainless Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Screw Diameter

- Customizable

- Power

- 2.2 kW

- Weight (kg)

- 680 kg

- Dimension (L*W*H)

- 1800 mm x 900 mm x 1500 mm

- Color

- Industrial Grey

About Shoulder Cap Assembly Machines

Understanding the dynamic nature of todays market, we are indulged in manufacturing, exporting and supplying a wide range of Shoulder Cap Assembly Machines. Provided machines are widely used for assembling cap for fitting in the bottles. These machines are manufactured by utilizing optimum quality components and latest advanced technology as per the instructions provided by our team of deft professionals. Our clients can purchase these Shoulder Cap Assembly Machines from us in different technical specifications at a competitive price range.

Features:

-

Easy to operate

-

Less maintenance

-

Low power consumption

-

Sturdy construction

Precision and Speed Combined

Engineered for speed and accuracy, the Shoulder Cap Assembly Machine leverages advanced PLC controls to automate the cap assembly process. Its customizable settings enable seamless integration into diverse production lines, ensuring high-quality results every time.

Built to Last in Industrial Settings

Crafted from top-grade stainless steel and designed in a durable industrial grey finish, this machine is robust enough for demanding factory environments. Its electric drive mechanism enhances longevity and operational efficiency, minimizing maintenance needs.

FAQs of Shoulder Cap Assembly Machines:

Q: How does the Shoulder Cap Assembly Machine operate?

A: This machine utilizes a PLC control system to automate the shoulder cap assembly process, minimizing manual intervention. Simply load the components, set the desired specifications such as screw diameter, and the system manages assembly with precision and efficiency.Q: What are the main benefits of using this automatic assembly machine?

A: Key benefits include improved assembly speed, consistent output, and significant labor savings. The automated process reduces the potential for human error and ensures uniform quality for each assembled unit.Q: When is it advisable to use the Shoulder Cap Assembly Machine?

A: It is ideal for manufacturers seeking to enhance efficiency in shoulder cap assembly lines, especially for medium or large-scale production where high throughput and reliability are essential.Q: Where is this machine best installed in the production process?

A: The Shoulder Cap Assembly Machine is best positioned after initial component preparation and before final product packaging. Its compact footprint allows easy integration into existing production layouts.Q: What is the process involved in customizing the screw diameter?

A: To accommodate various product requirements, users can easily adjust settings on the PLC interface to specify the desired screw diameter. This flexibility supports a range of cap sizes and types.Q: How is the machine maintained for optimal performance?

A: Routine maintenance involves cleaning stainless steel surfaces, checking electrical connections, and inspecting moving parts according to the manufacturers schedule. The robust construction ensures minimal downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automation Machinery Category

Cap Scoring Machine

Price 1000000 INR / Number

Minimum Order Quantity : 1 Number

Computerized : Yes

Automatic Grade : Automatic

Control System : PLC Control

Color : White

Flip Closing Machine

Price 1000000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Automatic Grade : Automatic

Control System : PLC Control

Color : silver

Cap Closing Machine

Price 1000000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Automatic Grade : Automatic

Control System : PLC Control

Color : silver

Custom Designed Machines

Computerized : Yes

Automatic Grade : Automatic

Control System : Other, PLC Based

Color : Industrial Grey / Custom Options

|

KENN ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry