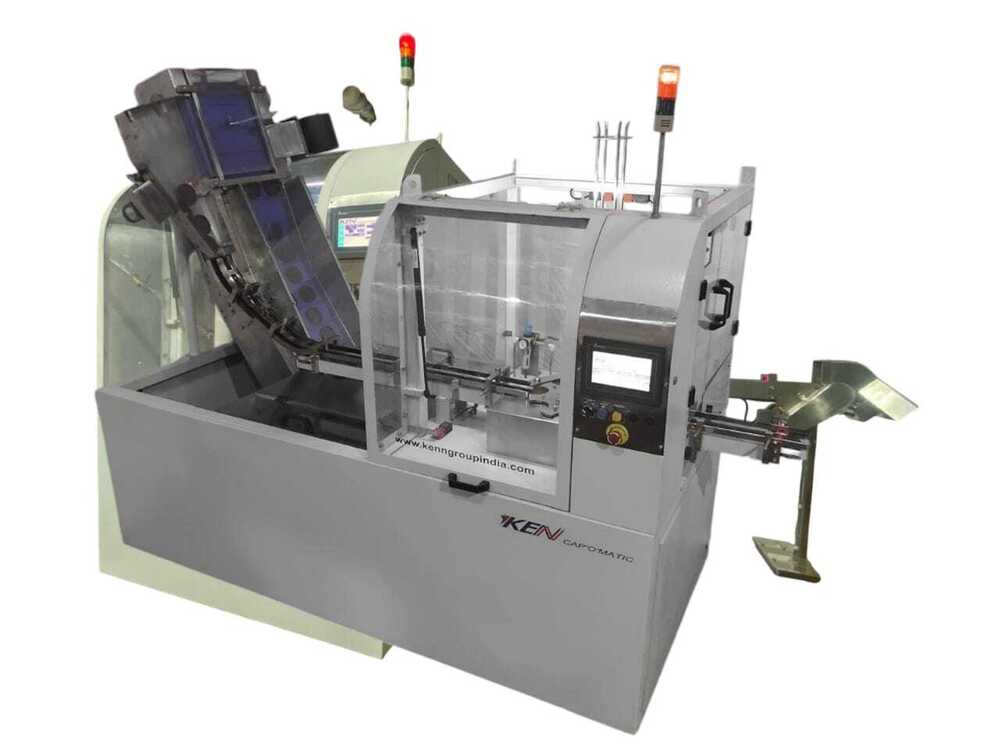

Flip Top Cap Closing Machine

Flip Top Cap Closing Machine Specification

- Type

- Flip Top Cap Closing Machine

- Material

- Stainless Steel (SS304)

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control Panel

- Drive Type

- Electric Motor

- Power

- 2.5 kW

- Weight (kg)

- Approx. 450 kg

- Dimension (L*W*H)

- 2100 x 900 x 1800 mm

- Color

- Stainless Steel Finish

About Flip Top Cap Closing Machine

Automatic Flip Top Cap Closing Machine

Flip top cap closing machines are used to close the open flip top of the cap automatically which is in open condition while it is molded. The other methods of closing the flip top caps are either manually or by 'in mold closing' (IMC) molds.

If done manually, it involves a lot of man power which is un hygienic, in consistent and non reliable and non economical if the quantity is very large.

It it is done by IMC for a given size of mold, the no. of cavities that is possible in it is 50% or lesser due to the two line layout of cavities constraint. In other words, if the IMC mold should have the same no. of cavities as that of a normal mold, the size of the mold would be 200%

or more bigger than the normal one, which can be loaded on a very high tonnage machine. More over the cycle time of the process is increased since the closing of the caps is done before ejection which requires some amount of time. Again the IMC mold cost is much more than that of the normal mold. All these above mentioned states that the cost of production increases to a very huge extent along with higher investments and larger payback period.

Here comes the relevance of the automatic flip top cap closing machine which is cost effective, consistent, reliable, hygienic, non labour oriented with low investment and very low pay back period.

Here comes the relevance of the automatic flip top cap closing machine which is cost effective, consistent, reliable, hygienic, non labour oriented with low investment and very low pay back period.

Speed: 60 to 120 caps per minute.

Advanced PLC-Controlled Automation

With a PLC control panel at its core, the Flip Top Cap Closing Machine offers fully automated operation, drastically reducing manual intervention and increasing production accuracy. Its computerized features allow easy programmability for various cap sizes and types, ensuring flexibility for diverse manufacturing needs. This automation is essential for manufacturers aiming for operational efficiency and reliable output in demanding production environments.

Robust and Hygienic Stainless Steel Build

Manufactured from high-grade SS304 stainless steel, the machine is designed to withstand rigorous industrial use. Its smooth, stainless steel finish not only enhances durability but also ensures easy cleaning, meeting hygiene standards especially important for food, cosmetic, and pharmaceutical industries. The corrosion-resistant structure extends the machines service life and maintains its performance under continuous operation.

FAQs of Flip Top Cap Closing Machine:

Q: How does the Flip Top Cap Closing Machine operate?

A: The machine operates automatically using an electric motor and a PLC control system. After setup, containers pass through the unit, where the caps are securely closed in a continuous, streamlined process, delivering consistent results with minimal operator supervision.Q: What materials is the Flip Top Cap Closing Machine made of?

A: This machine is constructed from SS304 stainless steel, which ensures durability, resistance to corrosion, and compliance with hygiene standards required in various industries.Q: When is it advisable to use this type of cap closing machine in production?

A: The Flip Top Cap Closing Machine is ideal for high-volume manufacturing environments where speed, precision, and hygiene are critical, such as in food, cosmetics, and pharmaceutical packaging lines.Q: Where can the machine be installed within a production facility?

A: Due to its dimensions (2100 x 900 x 1800 mm) and integrated design, the machine can fit seamlessly into existing automated production lines or standalone as part of new bottling or capping operations.Q: What is the process involved in cap closing with this machine?

A: The process begins by feeding containers with caps into the machine. Through synchronized movements, the unit automatically positions and tightly seals each cap using PLC-controlled mechanisms for accurate and reliable closure.Q: What are the key benefits of using a computerized, automatic Flip Top Cap Closing Machine?

A: Automating the cap closing process increases productivity, ensures consistent seal quality, reduces labor costs, and minimizes the risk of contamination, enhancing overall manufacturing efficiency and product safety.Q: How does the stainless steel finish benefit the machines usage?

A: The stainless steel finish ensures easy cleaning and maintenance, helping maintain sanitary conditions and extending the machines operational lifespan, especially in industries with strict hygiene requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automation Machinery Category

Cap Wad Assembly Machine

Price 1000000 INR / Number

Minimum Order Quantity : 1 Number

Drive Type : Other, Electric Motor Driven

Capacity : 4000 to 7000 Pieces/Hour

Automatic Grade : Automatic

Control System : Other, PLC Based

Cap Scoring Machine

Price 1000000 INR / Number

Minimum Order Quantity : 1 Number

Drive Type : Other, Electric

Capacity : 50100 caps/min

Automatic Grade : Automatic

Control System : PLC Control

Cap Lining Machine

Price 1000000 INR / Number

Minimum Order Quantity : 1 Number

Drive Type : Other, Electric

Capacity : 1200 caps/hour

Automatic Grade : Automatic

Control System : PLC Control

Switch Assembly Machine

Drive Type : Other, Electric

Automatic Grade : Automatic

Control System : PLC Control

|

KENN ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry